Modexpress - EcoPocket® für ein effizientes Multi-Client Fulfillment

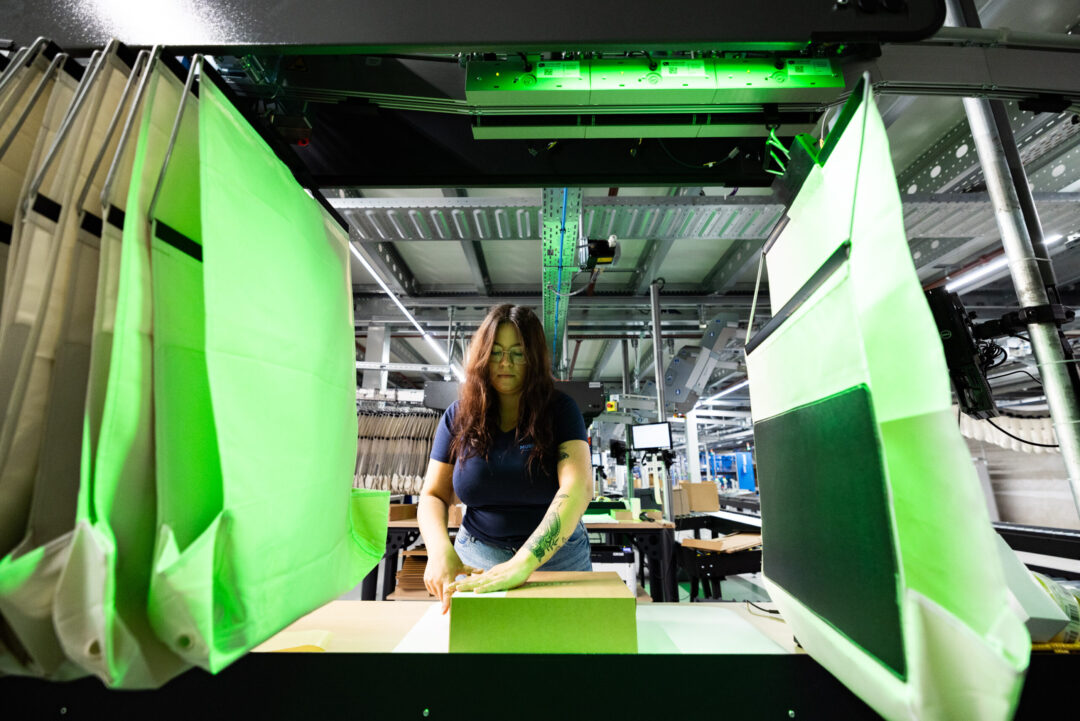

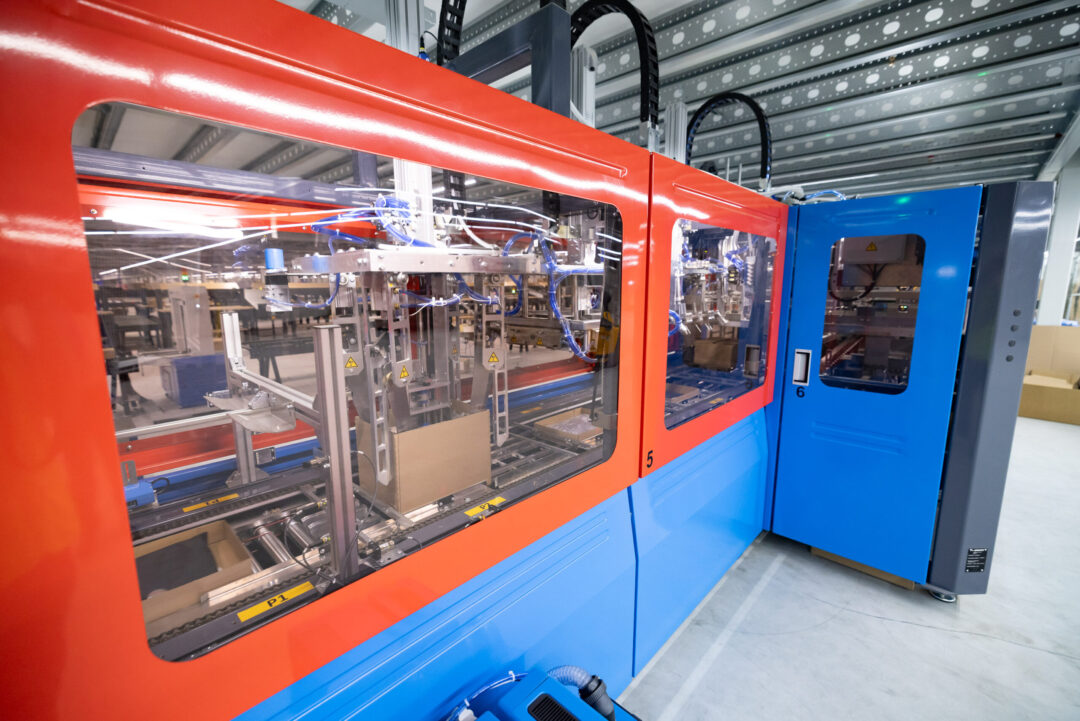

Modexpress uses DFT’s EcoPocket® as a key part of its automated warehouse processes. The result is a super modern fulfillment system that’s highly versatile and powerful.

Highlights at a glance:

- Multi-channel & multi-client fulfillment in one system

- Processing of a wide variety of items – from fashion to cosmetics

- Flexible inducts: manual & semi-automatic

- Intelligent sorting, sequencing, and shipping preparation

- Efficient processes thanks to modern SCADA interface